Portal Milling Machines

FX Series

- High speed milling

- Small foot-print

- Versatility

- User friendly interface

Max. X travels — 8100 mm

Max. Y travels — 1500 mm

Vacuum Pumps from 600 cmh

Standard vacuum table

- Integrated FANUC controller and servomotors

- Two software options – professional industrial FANUC software and easy to use customised software

- Easy operation of the machine even for CNC operators with no experience

- 21″ industrial touchscreen

HIGHLIGHTS

FX Series

Portal Milling Machines

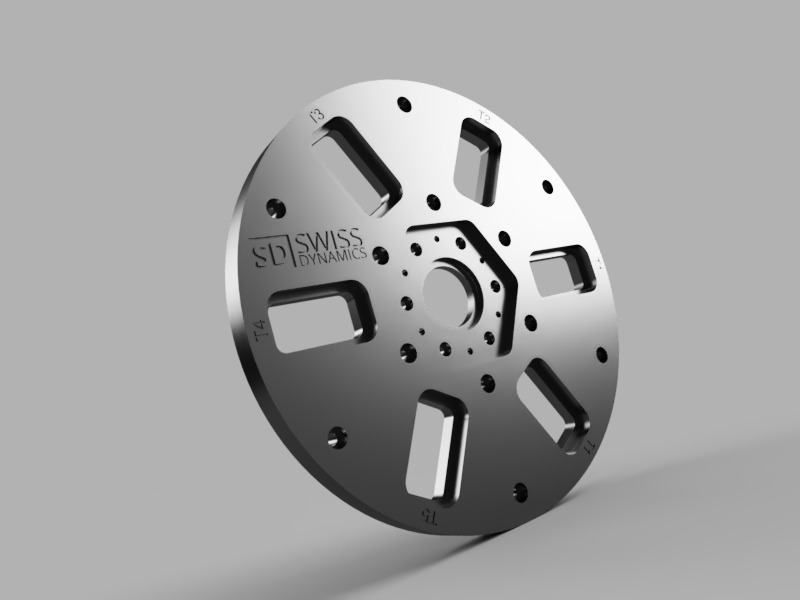

Spindle is the heart of the FX Series

PRECISE, FAST AND POWERFUL

Swiss Dynamics spindles are world leaders in precise, fast and powerful rotation.

We collaborate with international technology leaders, particularly in precision spindle construction. As a technology group, we develop and build high-tech products with significant added value for our customers.

We offer a varied range of spindles with a speed of up to 60000 rpm and a power of up to 15Kw

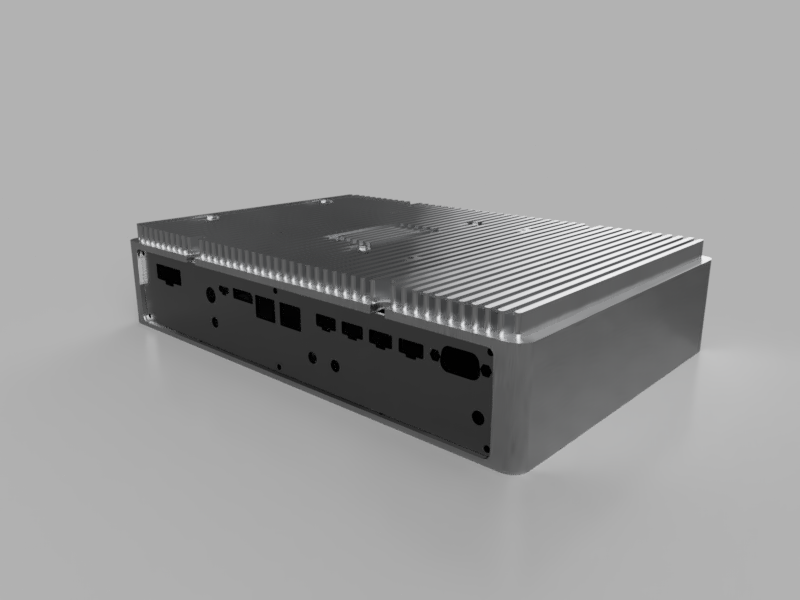

Controller and

Software

Accurate, Fast and Precise

Swiss Dynamics is powered by industrial Fanuc CNC controllers.

High Precision: Fanuc CNC controllers are known for their exceptional precision and accuracy in controlling machine movements. This ensures that the final product meets the required specifications.

User-Friendly Interface: Fanuc CNC controllers have a user-friendly interface that allows operators to easily program and operate the machine. The interface is intuitive and provides clear instructions for setting up and running the machine.

Advanced Motion Control: Fanuc CNC controllers offer advanced motion control capabilities, allowing for precise and smooth movement of the machine. This ensures high-quality machining and reduces the risk of errors or defects.

Applications

Mechanical part

Material: Al 5083

Dimension: dia. 320 mm x 20 mm

Machining time: 53 min

Automation

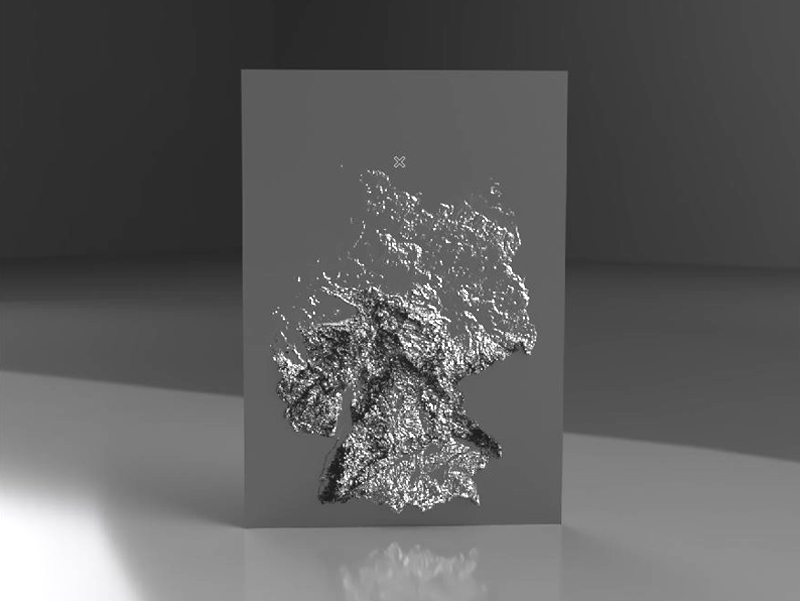

Mold

Material: Al 5083

Dimension: 200 mm x 150 mm x 12 mm

Machining time: 45 min

Plastic Industry

Mechanical Gear

Material: Brass

Dimension: dia. 76 mm x 9.6 mm

Machining time: 34 min

Energy Industry

Electronic Case

Material: Al 5083

Dimension: 180 mm x 120 mm x 50 mm

Machining time: 51 min

Aerospace Industry

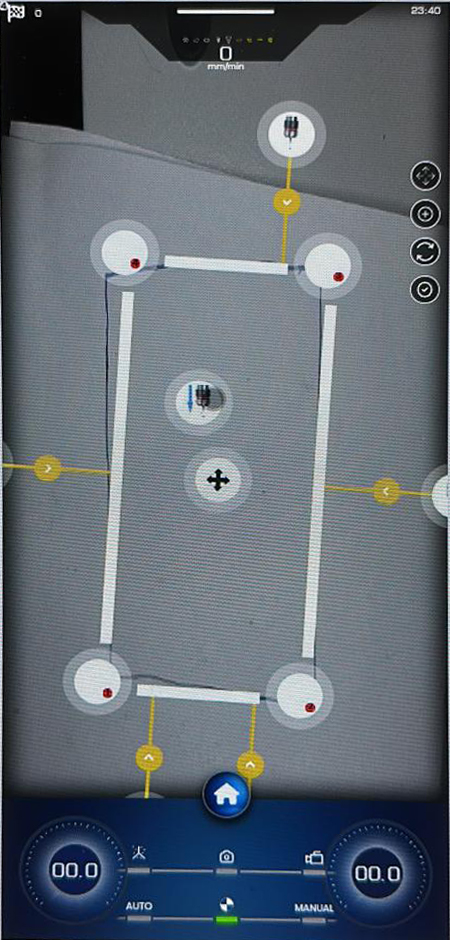

Software & Controller

AI User Experience

A special experience

Highlight of software:

• Excellent interface with simple touch operation

• Easy part alignment using camera

• Display 3D Model of a program preview

• Manual Jog of the machine using touch monitor

• Automatic tool measurement

Highlight of controller:

• AICC 2 - 1024 lookahead instruction

High speed machining required for keep the speed and precision position in advance of a program

• Dynamic mode acceleration - 0.15G Fine / 0.4 Standard / 1 G Fast

• Fine surface option included

• Pitch compensation and straightness compensation

Service

All-round worry-free package for your new machine!

When it comes to servicing high-speed machining equipment, there are several key highlights to consider. Here are some of the highlights for servicing high-speed machining:

1. Regular Maintenance: High-speed machining equipment requires regular maintenance to ensure optimal performance and longevity. This includes routine inspections, cleaning, lubrication, and calibration of the machine components.

2. Specialised Training: Servicing high-speed machining equipment often requires specialised knowledge and training. Technicians should be well-versed in the specific requirements and intricacies of high-speed machining technology to effectively diagnose and address any issues that may arise.

3. Precision Calibration: High-speed machining equipment operates at extremely high speeds and tolerances. As such, precise calibration of the machine's components, such as spindles, tool holders, and linear guides, is crucial for maintaining accuracy and minimising vibration or tool deflection.

4. Monitoring and Diagnostics: Implementing monitoring and diagnostic systems can help identify potential issues before they lead to machine downtime or damage. This includes real-time monitoring of spindle speed, temperature, vibration, and other critical parameters to detect abnormalities and take proactive measures.

5. Collaboration with OEMs: High-speed machining equipment is often complex and may require collaboration with original equipment manufacturers (OEMs) for servicing and repairs. OEMs can provide technical support, access to spare parts, and specialised knowledge to ensure proper maintenance and operation of the equipment.

Photo gallery

Download & Technical DATA

Downloads

FX Series brochure (e-Paper /PDF)

Models

FX 3015

-

Max X travels - 3,100 mm

-

Max Y travels - 1,500 mm

FX 4515

-

Max X travels - 4,600 mm

-

Max Y travels - 1,500 mm

FX 6015

-

Max X travels - 6,100 mm

-

Max Y travels - 1,500 mm

FX 8015

-

Max X travels - 8,100 mm

-

Max Y travels - 1,500 mm

Configurator

Configure your new

Portal Milling Machine - FX SeriesWould you like to configure your machine yourself?

Experience the possibilities of our technical solutions online!

The brand new Swiss Dynamics machine configurator offers you the perfect basis!

You can adapt the FX Series to your individual needs simply, intuitively and clearly.

Anytime, anywhere! Start now!